Electric cars are still a growing force in the automobile market, despite low gas prices in the U.S. for the last two years. The industry is seeing research innovations and consumer demand equally propelled by the desire to maximize green energy opportunities and harness the potential of autonomous vehicles. However, the modern electric car design is still held back by its biggest asset and weakness: the lithium-ion battery. But many of these drawbacks could change soon thanks to a research project at Ohio State University, which allows electric car batteries to recharge faster and provide more miles per charge.

Electric cars are still a growing force in the automobile market, despite low gas prices in the U.S. for the last two years. The industry is seeing research innovations and consumer demand equally propelled by the desire to maximize green energy opportunities and harness the potential of autonomous vehicles. However, the modern electric car design is still held back by its biggest asset and weakness: the lithium-ion battery. But many of these drawbacks could change soon thanks to a research project at Ohio State University, which allows electric car batteries to recharge faster and provide more miles per charge.

The research team from Ohio State University designed a new material using a modified covalent organic framework that could let electric cars charge faster and increase their driving range. The new framework materials, which looks like a thin plastic membrane, allows one device to store large amounts of electrical energy or charge, like a standard lithium-ion battery, and to charge and discharge that energy rapidly, similar to what a supercapacitor does.

The membrane essentially separates the anode and cathode with a cell-like latticework to stop a rechargeable battery from discharging when it’s not in use, but still allows for rapid recharging. It’s similar to how cell walls expand and contract to let the body process biological functions.

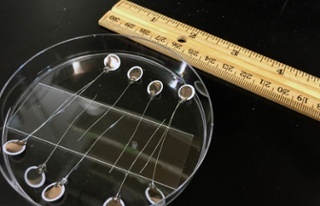

The “smart membrane,” as the researchers call it in a press release, combined an electrically conductive polymer with a polycarbonate filter used for air and water testing. By controlling how the conductive polymer chains grew on the polycarbonate surface, the researchers discovered they could control the density of openings in the membrane, the release states. When they swell the polymer if the battery isn’t in use, then the membrane seals itself and prevents ions from discharging by leaking between the anode and cathode, which maintains a constant battery capacity. And the opposite happens if they shrink the membrane; the cell-like walls open and allow for ions to rapidly flow and recharge.

In laboratory tests, the engineers used batteries powered by ions of lithium, sodium and potassium and discovered that their membrane reliably controlled charging and discharging in all three chemical compositions. They connected the batteries to an LED light, and programmed the membrane holes to open and close in precise patterns, the release states. The membrane allowed the batteries to function normally and power the LED for 30 seconds, and then reduced the charge loss to zero when the batteries were not in use.

These findings—if proven consistent enough for commercial manufacturing—are huge because energy discharge and charge time are the main drawbacks in standard lithium-ion electric car batteries.

Although lithium-ion batteries are developed with conductive membrane walls that physically separate the anode and the cathode, the batteries still lose charge capacity over time because standard membrane materials can’t completely prevent the ionic charge from leaking between the anode and cathode and dissipating, Travis Hery, an OSU doctoral student, explained in the press release.

If this technology comes to fruition then it could revolutionize the electric car industry, and make electric engines finally rival the efficiency of standard combustion engines.

During the research phase of their experiment, the OSU researchers analyzed the performance of the leading hybrid and electric car batteries, and they discovered the best environmentally-friendly car manufacturers appear to have hit a performance limit of 0.4 miles per minute of charging, according to the paper the team published in the journal Energy & Environmental Science.

That means today’s top-of-the-line hybrid and electric cars can travel roughly 200 miles after an 8-hour charge cycle. Compared to gas combustion engines, which can cover the same distance after only one minute spent at the pump, and it’s clear to see there is still room for big innovations.

The researchers said in their published paper they hope their new technology can improve electric car batteries to provide up to tens of miles per minute of charge.

It’s likely going to take a few more years of research and experimenting to discover whether the researchers achieve their goal. However, if you’re in the need of electric vehicle batteries or simply want to learn more about current lithium battery technology, then get in touch with us.

Information for this report was provided by the Ohio State University.