The first generation of lithium batteries offered immediate advantages over lead-acid batteries, but they still left users wanting more. Just because lithium batteries solved the issues of partial state of charge, charging procedures, maintenance, and battery life didn’t mean they didn’t create new problems, or, more precisely, higher expectations.

RELiON designed the InSight series around those problems and expectations. We set out specific design criteria based on our analyses of where existing lithium batteries fell short and resolved not to bring a battery to market unless it satisfied every criterion. Let’s take a look at a few features of the InSight that we developed based on what wasn’t there before.

- Easy Drop-In Replacement

- Power based on your capacity needs

- Smart hardware design

- Ability to handle regen currents

- Smart software design and Battery Management System

Ease of use: Drop-in, ready to go

The one area where RELiON wanted to be completely conformist and absolutely unoriginal was in the size and shape of the battery. We did not want anyone to have to change anything about their vehicle other than their batteries. The most difficult part of the installation is removing your heavy lead-acid batteries.

The InSight 48V fits into the standard battery trays for golf cars, low-speed vehicles, or utility vehicles.

Once you place the batteries into the tray, utilizing the battery cables they’re connected in parallel, which means the positive terminals are connected together and the negative terminals are connected together. Once the battery cables are connected, you then connect the CAN cables, and this is just as easy: connect the CAN Out of one battery into the CAN In of the next battery, the CAN Out of that battery into the CAN in of the next, and so on.

The CAN Cable Connection is not required to use the batteries, but it enables our Bullseye Balancing, the first of several “smart” features within InSight. The batteries share information with each other via CAN communication so they balance automatically.

How much capacity do you need? How much do you want?

Lead-acid and other lithium batteries need to be connected in series so you can get 48 volts from your array. But each InSight battery is 48 volts, meaning you can simply connect them in parallel to customize the capacity you need.

Although you can connect up to 10 InSight batteries in parallel. With InSight, this provides a capacity of 300 Amp-hours. That converts to about 120 - 150 miles per charge.

This may seem high based on other batteries you’ve owned and your back-of-the-napkin math, so this is a good time to mention that each InSight 48V battery is 34 pounds, about half the

weight of a lead-acid battery. The combination of greater capacity and less weight is a double benefit to your distance per charge.

Most people will use 2-3 InSight batteries in their golf carts to get the same range as their previous lead-acid batteries.

Smart hardware design keeps the battery calm and cool

If lead-acid batteries are rotary telephones and lithium batteries are cell phones, the InSight is the iPhone X. The hardware and software of the battery monitoring system (BMS) make RELiON’s InSight as smart as any “smart” device you’re already using.

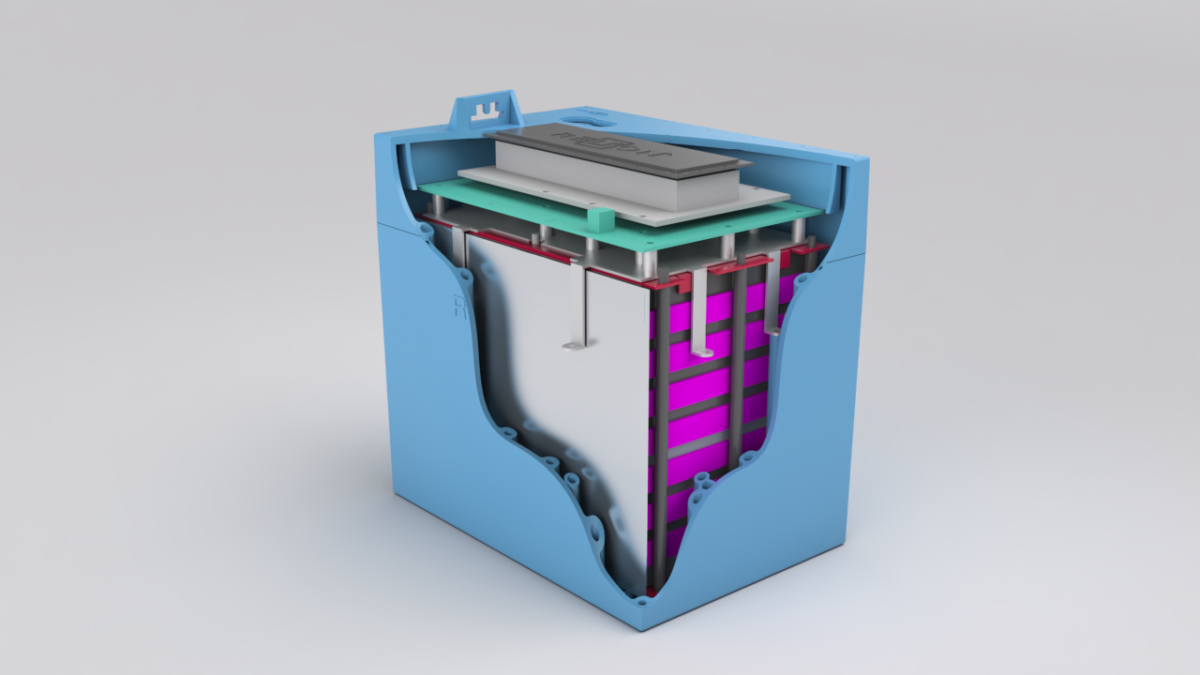

InSight’s BMS hardware is an entirely solid-state - there are no moving components. This makes the battery more durable, particularly if you have it installed in a utility vehicle, and keeps the operations of the battery much smoother. Sometimes under abrupt conditions, traditional lithium batteries with electromechanical components will have little hiccups. InSight’s hardware eliminates those, as does the software, as we’ll see below.

Another design advantage to using solid-state components is heat generation and dissipation. Solid-state components generate less heat, by design. InSight batteries use a lot of components on each board, more than any other BMS. On its own, this could lead to heat building up. But the arrangement of the individual components and the spacing of the boards dissipate heat more efficiently and more fully than any other battery, keeping the circuitry at an optimal temperature for operations and prolonging the life of the battery.

The other feature that keeps the temperature low inside the battery is the heat sink. The RELiON nameplate on the top of the battery is there because of the engineers, not the marketers.

Putting the heat sink on the top of the battery gives the heat generated by all the electronics a path to the outside world. Most batteries have their heat sink within the battery if they have one at all, which shuffles the heat away from the electronics but still traps it, causing the internal temperature to rise during extended use.

Research-driven ability to handle regen currents

Processing regeneration currents is one of the most challenging features of a lithium battery and with InSight we rose to the challenge with a unique solution. To protect the battery, there has to be a limit to the magnitude of the regen current that reaches the battery, particularly when the batteries are at a high state of charge. This necessary safety design causes traditional lithium batteries to disconnect when a regen current exceeds a preset magnitude and duration. When the batteries are being used to power a vehicle and they see a regen current, they react to it as if a high-power charger was connected, and immediately go into a protective mode

causing them to disconnect. To bring the batteries back online, you need to disconnect then reconnect all cables.

RELiON took a few approaches to solve this problem. First, InSight has two inputs: one for charging currents and one for regen currents, and the batteries know the difference between the two types of current.

Our engineers got out of the lab and into golf cars so they could generate every profile of regen currents they could think of.

Using the data they produced, they set three different filters - combinations of amplitude and duration - to cover a wide range of regen currents. This minimizes spurious disconnections upon a regen current that doesn’t “fit” a profile.

Of course, there may still be times when disconnecting is the right thing for the battery to do. When that happens, because the InSight batteries are connected in parallel, there is no interruption to the output. One battery will disconnect and the others will keep operating at the same level as before. More than that: once the conditions are set for the battery to reconnect, it does so itself.

You will go through the entire process of regen current, disconnecting, and reconnecting without knowing anything about it.

Smart software design keeps the battery learning

We can’t be there optimizing every battery for the conditions you create throughout its lifespan, so we designed a battery that can optimize itself.

The BMS processes a wide number of inputs, and instead of simply calculating outputs the software’s algorithms learn about the battery in real-time. BMSs with standard algorithms can see their outputs drift over time as increasing variability in the data is processed through a fixed series of calculations. InSight’s BMS is constantly updating, so it grows more accurate and stays accurate over the life of the battery.

RELiON’s InSight series is the first lithium battery designed specifically around how they need to perform in golf cars, low-speed vehicles, and utility vehicles.

InSight 48V batteries are available for purchase online, as are most other RELiON products. You can also contact us directly if you have custom battery needs and want to apply RELiON’s design process and expertise to your requirements. Click here to learn more about how to install RELiON InSight Lithium Golf Cart Batteries.